Overview Systems for automated trolley loading and unloading

Automated trolley loading and unloading

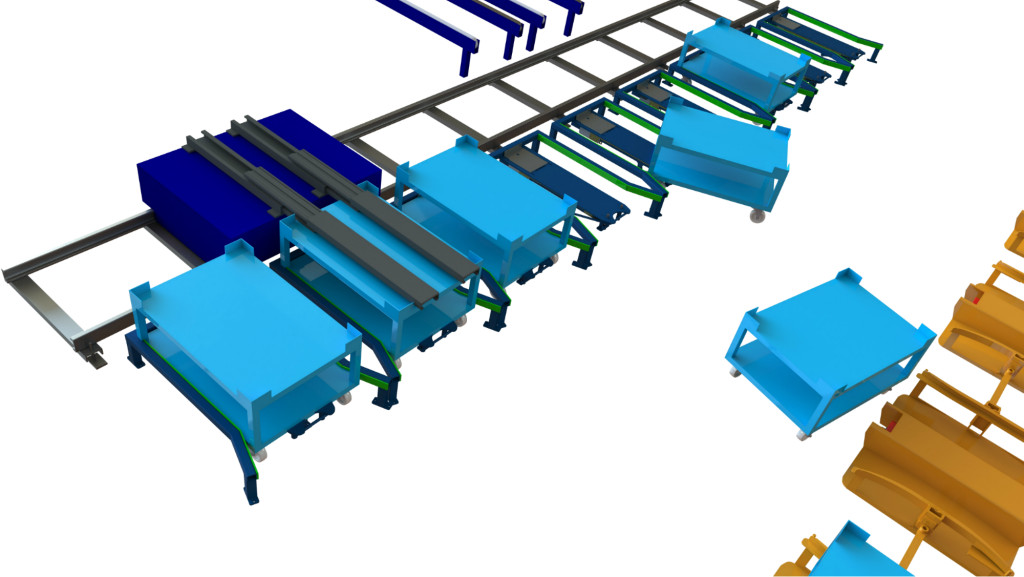

Trolley Hub

The “Trolley Hub” is a hub turret with solid pair of prongs, it can transform carriers: from conveyor system to conveyor system, from conveyor system to a trolley and / or from a trolley to conveyor system.

The “SHT Trolley Hub” is a flexible system that can set down all forklift capable containers, even on low trolleys without structural alterations or additional lifting mechanisms. The “SHT Trolley Hub” can also load pallets “crossway”, despite the continuous battens/lathing.

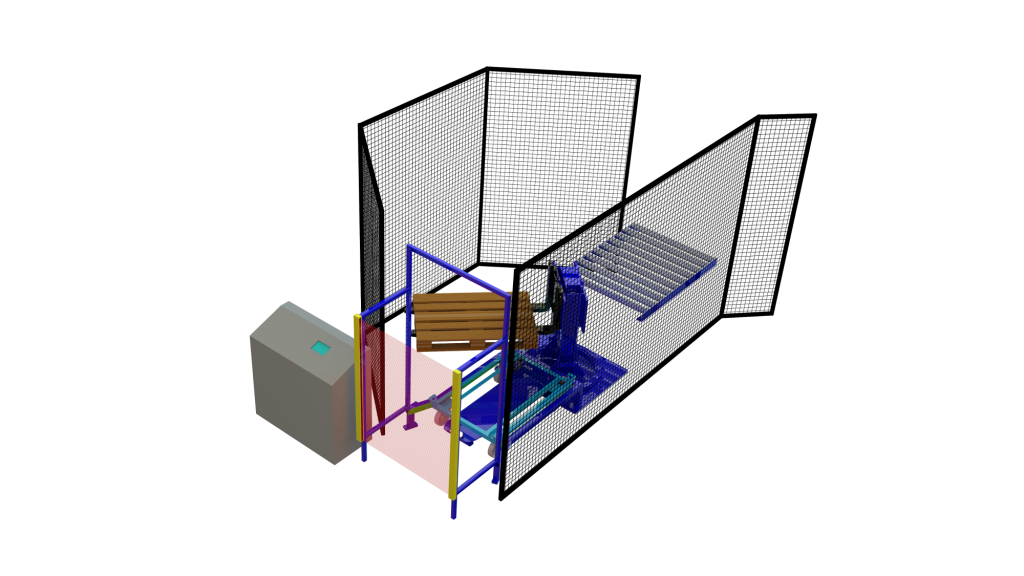

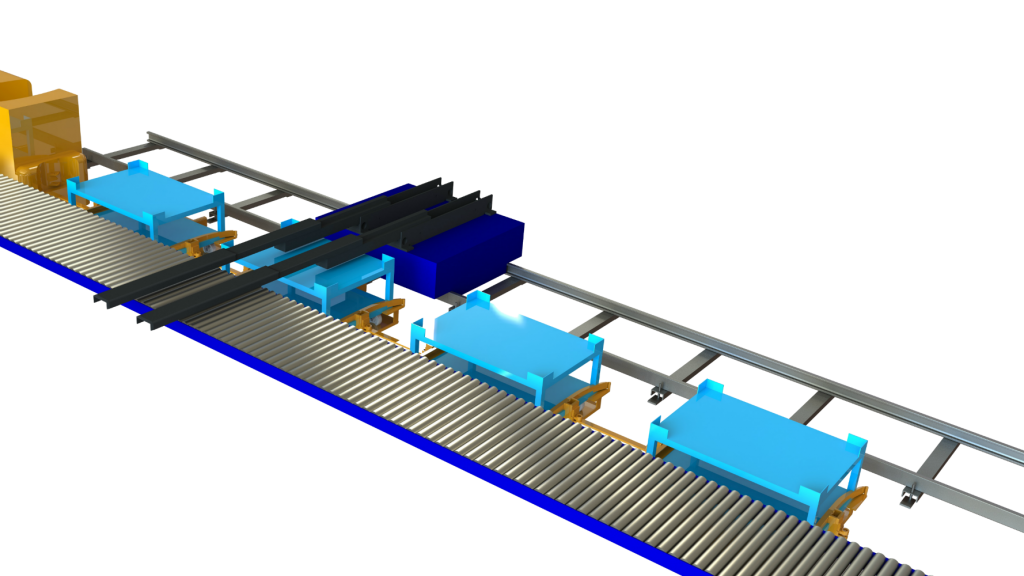

Portal Converter

The “SHT Portal Converter” can be used for automatic loading and unloading of carriers from conveyor systems to trolleys and vice versa.

The space saving design of the “SHT Portal Converter” requires only slightly more space than the carrier base, therefore it is much more compact than other handling equipment. The space saving design is achieved by a deviating pallet handling.

The trolley doesn’t have to present any minimum height, thus the Portal Converter can be used without further structural measures.

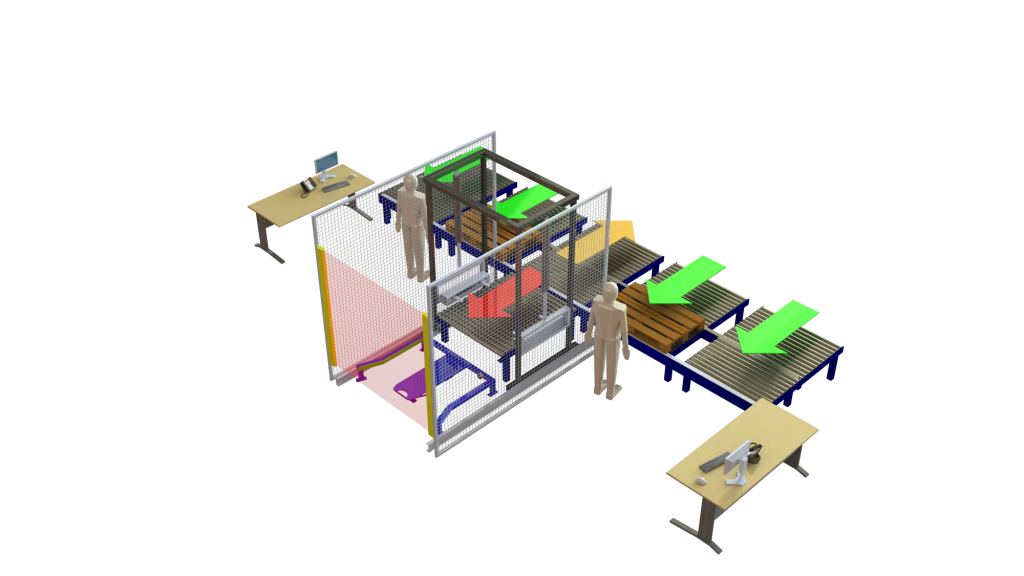

Movable Telescopic Table

As an extension of the stationary telescopic table, movable telescopic tables have the ability to serve multiple feeding and discharging stations as well as Trolley Docking Stations.

Providing multiple loaded trolleys eliminates the waiting time of a tugger train driver what makes the whole process more efficient. When the tugger train reaches the station, changing containers can start immediately. So the process in the warehouse is similar to the process on the line, which greatly simplifies the integration of the system.

Automated loading and unloading of tugger trains

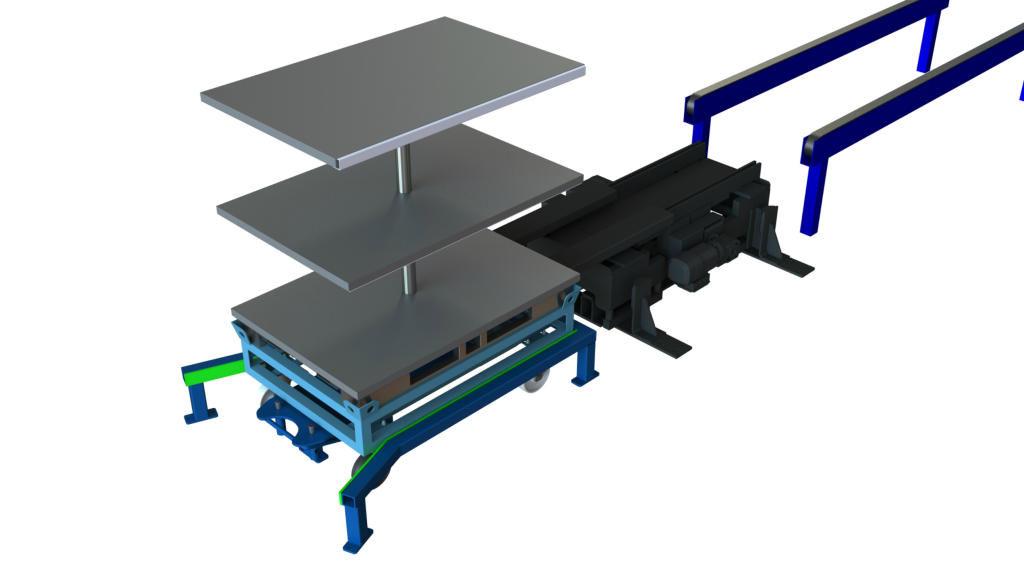

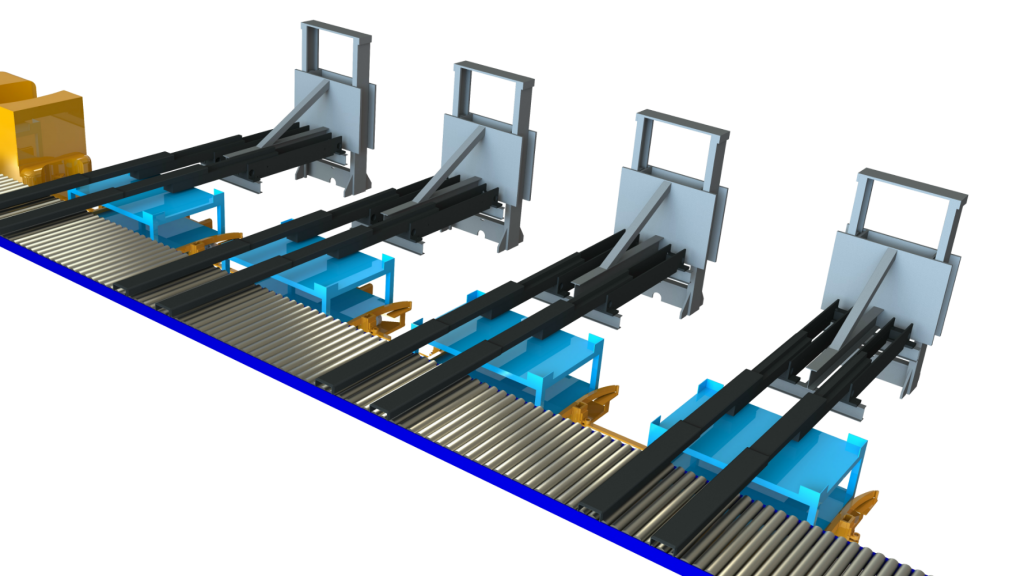

Movable Double-Deep Telescopic Prongs

By using double-deep prongs and an innovative station design the MBW solution makes it possible to relocate pallets crosswise. The tugger trains are positioned grossly through the entrance of the line between conveyor systems and telescopic tables. You get a process-safe system, because the system takes over the fine adjustment. The carriage picks up the carriers crosswise from the conveyor belt and puts it onto the trolley, which is located on the tugger train.

Double-Deep Telescopic Prongs

The previously described carriage can be dispensed if the tugger train moves fully automated in a super marked sector thus ensures a reproducible, highly accurate positioning. This expansion stage represents the precursor to a completely unmanned material supply. The worker can put down the tugger, which needs to be loaded, in front of the supermarket sector and immediately move on with an already loaded tugger. This way waiting times of logistician are completely eliminated. In this system the loading and unloading area is completely separated, which is why an interaction between employees and investment is excluded.